Stronger than concrete

In the past, concrete was the only option available on the market. But now, it’s time has finally come to an end. Compared to GoliathTech's helical (screw) piles, concrete is no match when it comes to strengthening, restoring, or building a foundation.

Resembling a large screw, screw piles are installed deep into the ground, beneath the ground freezing level, to solidly support the structure of your project. This is an advantageous alternative to form tubes and is less expensive than concrete foundations.

easy installation

Say goodbye to heavy machinery and long construction timelines. We install screw piles efficiently using compact, all-terrain equipment, allowing us to work in tight spaces with minimal site disturbance.

Our installation process eliminates excavation and curing delays common with concrete foundations. By installing directly to stable soil layers, we help projects move forward immediately and with confidence.

Rapid installation

Minimal impact to the landscape

No excavation

Start building immediately after installation

Perfectly level structure

Ideal for restricted spaces

Year-round installation

Removable and reusable

Low environmental footprint

Suitable in all soil conditions

No concrete required

Lifetime warranty

long-term savings

While a screw pile may cost more upfront than a bag of concrete, it becomes the more economical choice once installation is considered. GoliathTech helical piles install in a single day with one installer, minimal equipment, and little impact on the landscape—saving both time and labor costs.

Concrete foundations require excavation, heavy machinery, multiple workers, and curing time, and they are vulnerable to cracking from freeze–thaw cycles. They’re also far more expensive to remove if needed. In the end, a screw pile foundation delivers greater durability, faster installation, and lower overall project costs than concrete.

→ Smaller labor cost

→ Less working hours

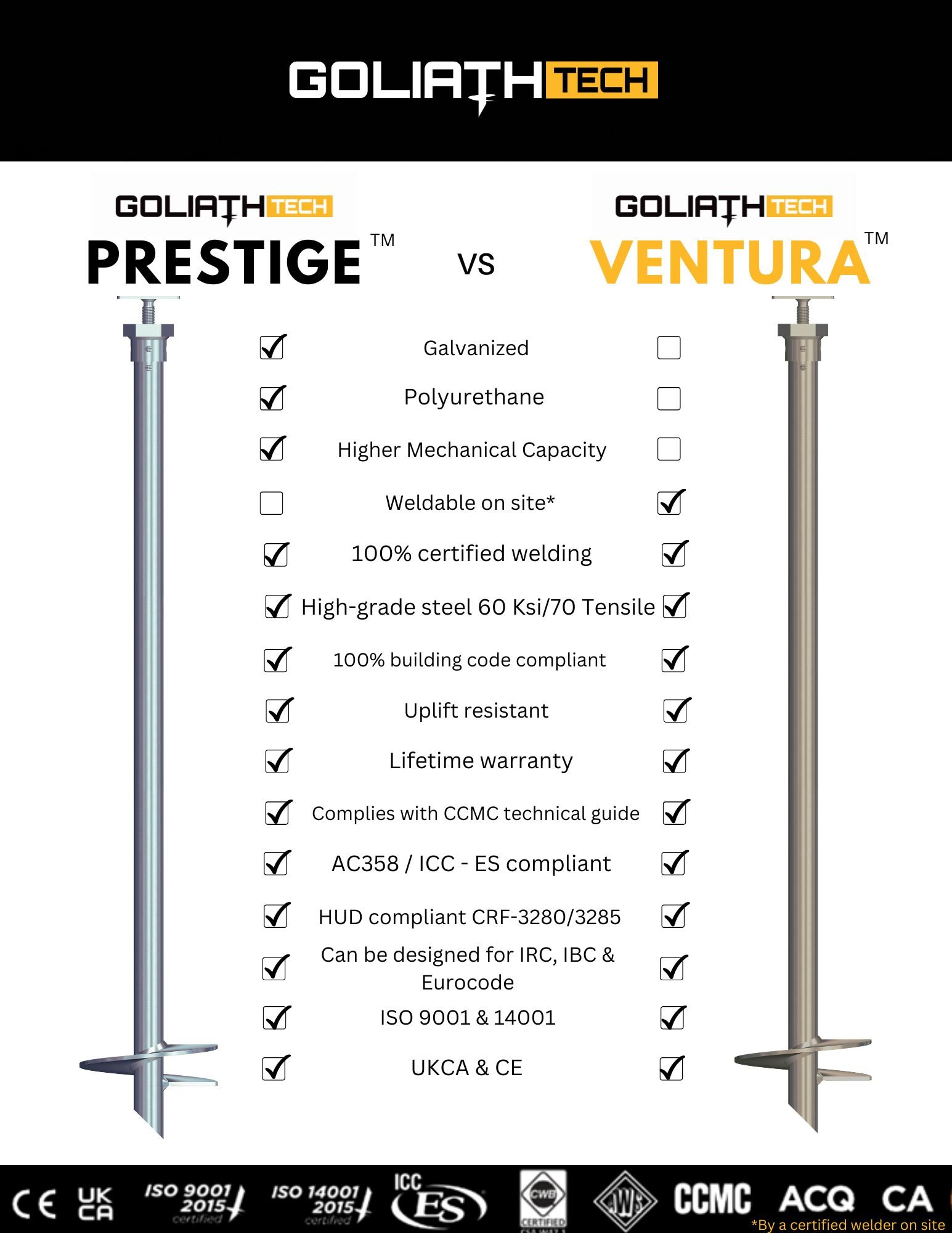

quality comes first

GoliathTech helical piles are engineered foundation systems designed for precise load transfer and accurate leveling. Unlike poured concrete, pile depth is adjusted in real time to reach competent bearing strata, ensuring predictable performance and structural stability.

A wide range of shafts, helices, caps, and accessories allows each installation to be engineered for specific loads, soil conditions, and environmental constraints. Installed by certified professionals, GoliathTech’s patented systems meet high industry standards and deliver long-term performance not achievable with conventional concrete foundations

Engineering expertise

Products that surpass the highest industry standards

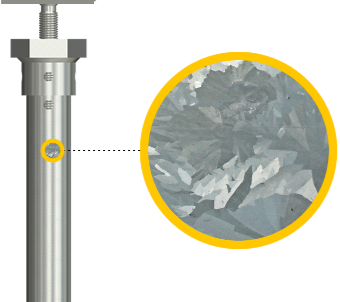

Concrete foundations can crack and shift over time, especially in cold climates where freeze–thaw cycles put constant stress on the structure. GoliathTech screw piles are built to withstand these conditions, using a high-quality galvanization process that protects against corrosion and long-term wear.

Screw piles anchor deep into stable soil and connect directly to your structure with a secure fastening system. This helps prevent settling, movement, and structural damage over the years. The result is a stronger, more reliable foundation that stays level and performs season after season—giving homeowners peace of mind and lasting value that traditional concrete simply can’t match.

durability that lasts

STEEL + ZN

Superior quality galvanized steel, worthy of the most ambitious projects

Our galvanizing process protects steel against corrosion to guarantee maximum product longevity. No matter the area where they are installed, GoliathTech piles remain in perfect condition for a very long time. It’s guaranteed!

GOLIATHTECH DOUBLE PROTECTION

Fights frost and thawing soil movements on all fronts: inside-out

Piles designed to last. Guaranteed.

→ The inside of GoliathTech piles is filled with polyurethane to prevent ice accumulation inside the pile. Polyurethane insulation maintains temperatures above freezing point.

→ The 60Ksi steel piles are fully galvanized to protect the tubes as well as the heads and helixes against physical deterioration.

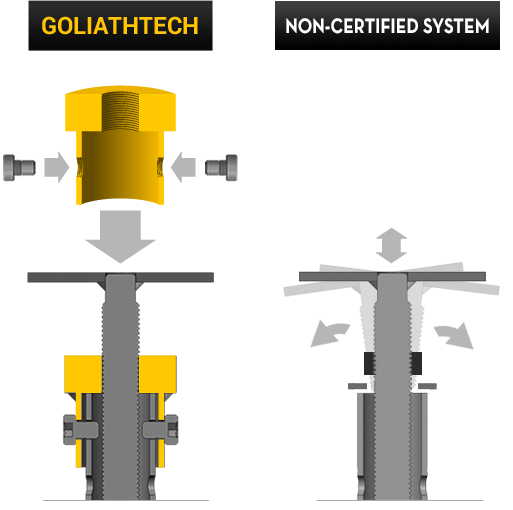

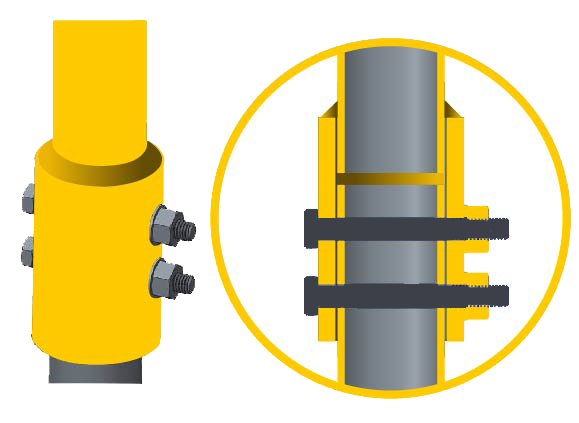

EXCLUSIVE ANCHORING SOLUTION

GoliathTech pile heads are equipped with a nut-fastening system. This exclusive anchoring solution allows the structure to be installed directly on the piles, thereby preventing lateral or vertical movement.

→ Zero movement

→ Superior resistance to wrenching

Piles with reinforced joints

The GoliathConnect joint system allows a pile to be extended by joining two tubes using a locking bolt. Contrary to the competition’s solution, this innovation strengthens long piles and eliminates risk of movement.

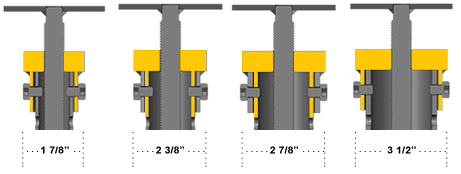

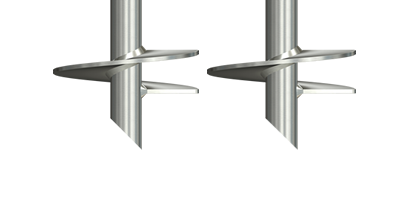

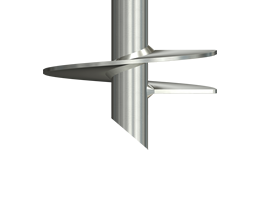

GoliathTech offers a vast array of tubes and helices according to the weight to be supported and the type of soil. Each GoliathTech product is thus perfectly suited to your project.

CHOOSING THE RIGHT PILE

Light Structures

Ideal for:

— Balconies and galleries

— Patios

— Sheds

— Fences

Average Structures

Ideal for:

— Docks

— Solariums

— Walk-ways

Heavy Structures

Ideal for:

— Cabins

— Agricultural Infrastructure

— Extensions

— Building Foundations

— Bridges

turnkey solutions

If your project require custom made piles, we can offer turnkey solutions to meet your needs.

Certifications & Approvals

GoliathTech helical piles are engineered and certified to meet applicable building codes and industry standards.